What Is SLS 3D Printing?

Selective Laser Sintering (SLS) is one of the most advanced 3D printing methods used today.

It works by fusing powdered material with a laser, creating durable, detailed, and professional-quality objects — perfect for prototypes or real functional parts.

If you’ve been using FDM or resin printers, moving to an SLS printer in 2025 can take your designs to a whole new level.

Top SLS 3D Printers in 2025

1. Formlabs Fuse 1+ 30W

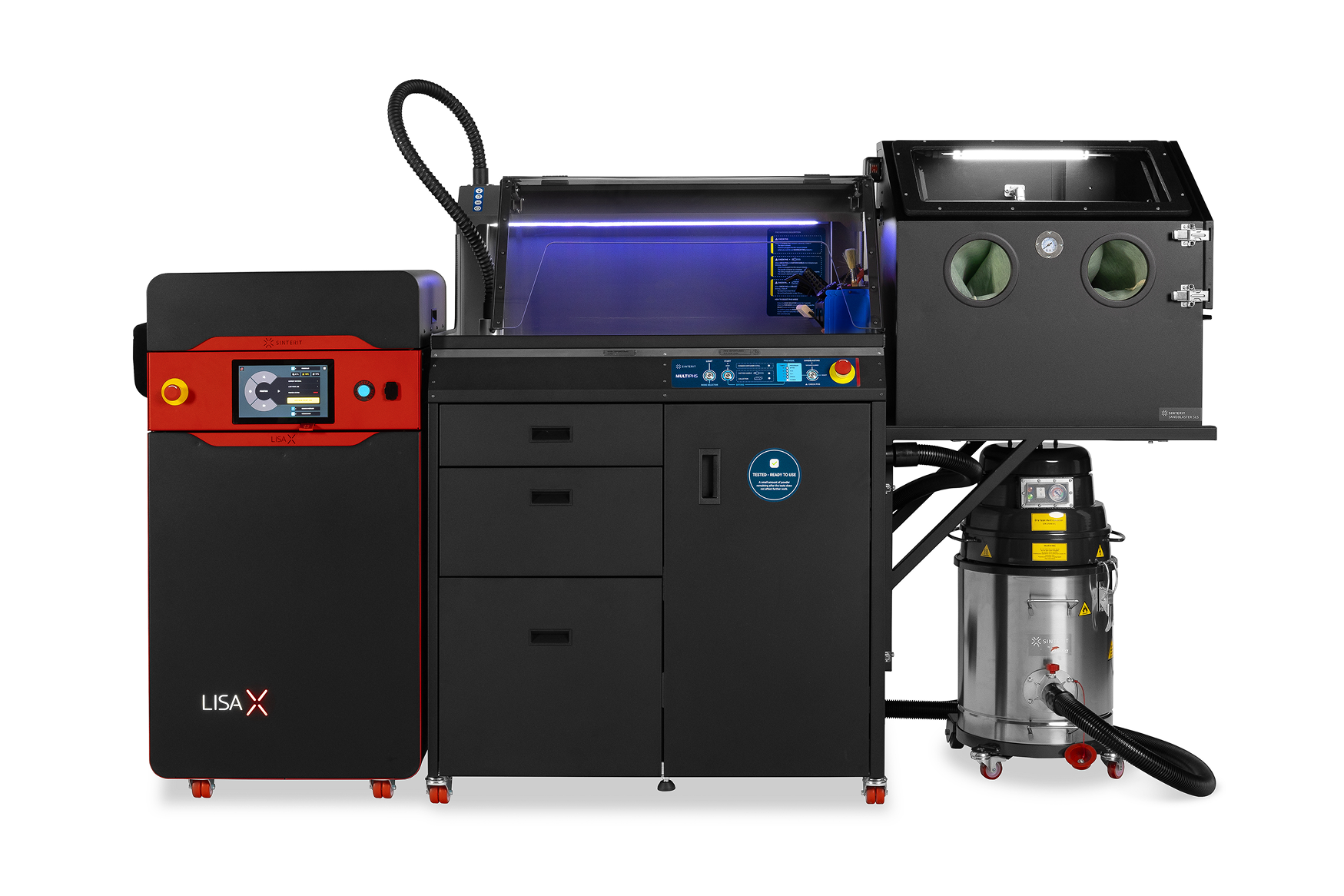

2. Sinterit Lisa X

- Build volume: 130 × 180 × 330 mm

- Material: PA11, PA12, Flexa Grey

- Highlights: Desktop-sized SLS printer with professional quality.

- Perfect for: Design studios, engineers, and education.

3. Sintratec S3

- Build volume: 160 × 160 × 400 mm

- Material: PA12, TPE

- Highlights: Modular, upgradeable, open material platform.

- Perfect for: R&D labs and universities.

4. EOS Formiga P 110 Velocis

- Build volume: 200 × 250 × 330 mm

- Material: Industrial-grade nylon and composites.

- Highlights: Ultra-high precision and production-level reliability.

- Perfect for: Automotive and aerospace parts.

5. XYZprinting MfgPro230 xS

Build volume: 230 × 230 × 230 mm

Material: PA12, PA11Highlights: Affordable SLS option for small businesses.

Perfect for: Startups and makers.

Why Choose an SLS 3D Printer in 2025?

- Industrial Quality at Desktop Size — many modern SLS printers are now compact and office-safe.

- No Support Structures Needed — you can print complex parts easily.

- Durable Functional Parts — stronger than FDM and SLA prints.

- Open Material Options — from nylon to flexible TPU and composites.

At this point

SLS 3D printing is no longer limited to big factories — it’s becoming accessible to small businesses, designers, and even hobbyists. If you’re ready to upgrade your 3D printing setup in 2025, any of these SLS printers will deliver professional results with precision and speed.

0 Comments